Lab Automation Unconstrained by a Strict Definition

What is lab automation?

Lab automation involves controlling tools and equipment with minimal interaction. It integrates automated technologies into the laboratory to streamline processes and eliminate repetitive tasks, improving throughput and quality. It is essential for labs to remain competitive and meet demands, especially as they face challenges with resource limitations and complex workflows. Lab automation can range from automating specific tasks to entire workflow automation, providing significant benefits for laboratories.

Lab Automation: A Definition That’s Hard to Pin Down

Many individuals in life sciences use ‘lab automation’ when talking about their workflows or specific solutions they have developed. However, one rarely hears a consistent, hard-lined definition of the term; a sentiment echoed by many colleagues over many years.

In fact, ‘lab automation solutions can involve any number of digital and robotic technologies as demonstrated in the following examples:

- Automated liquid handlers, liquid handlers, liquid handling workstations – dispensing liquid volumes into microplates or other sample vessels, often with limited capacity for small integrated small devices

- Robotic arms – transporting microplates from one device to another in an automated workflow

- Automated sample stores, automated storage systems, robotic sample management systems – highly controlled environments to store, manage, and retrieve samples

- Automated dispensers, washers, – adding and/or removing liquid from a single microplate at a time

- Automated plate handlers, plate hotels – devices to store, manage, and transport microplates

- Automated microscopy, robotic imaging – systems to focus on, acquire, and analyze sample images

- Automated extraction, automated nucleic acid extraction, automated protein extraction – high-speed purification of DNA, RNA, or proteins from microplate-based cells

- Electronic notebooks and laboratory information management systems (LIMS) – digital record-keeping and data management systems

Highres Biosolutions holistic three-pronged approach to lab automation

However, for lab automation to truly benefit you or any lab, the emphasis should not focus on any one tool or action from the examples above. Why? Because automating one portion of an overall process shifts the potential for bottlenecks, variabilities, and limitations to upstream and downstream steps. This slows productivity and may put you at a competitive disadvantage. Instead, we recommend a holistic three-pronged approach to automation.

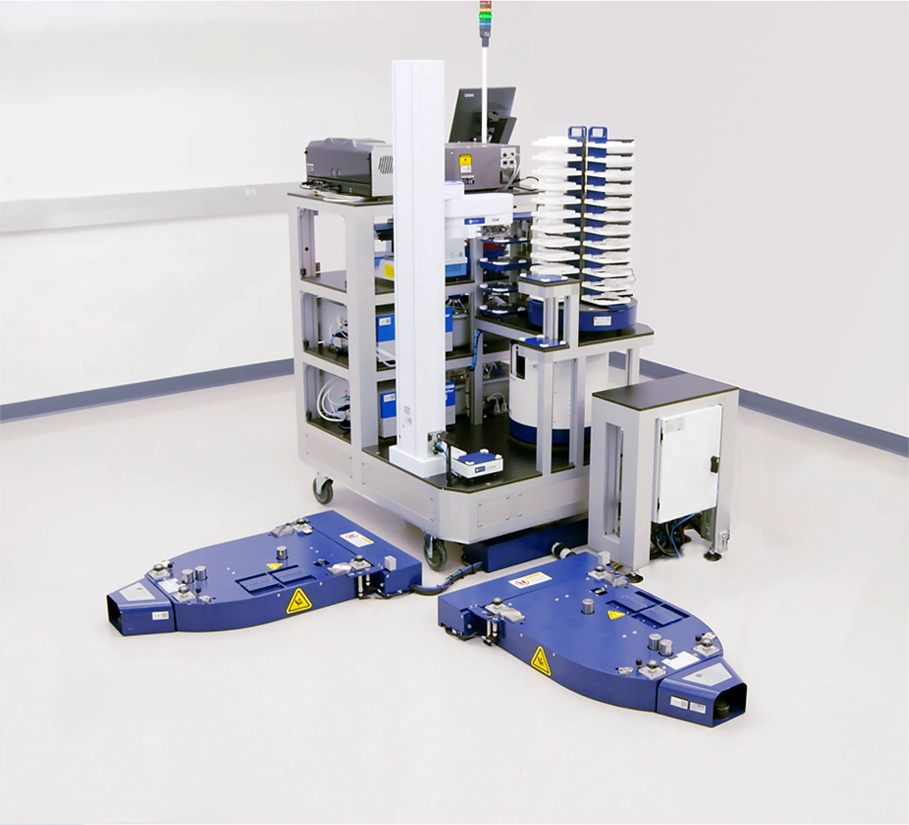

Category 1 – Hardware

In the trichotomy of lab automation, the first prong or tenet is hardware. Here, modularity is important. Using liquid handlers as an example, you may hear that deck size matters or that the liquid handler is the most critical component for your workflow in context of modularity.

While it is true that liquid handlers are an important component of an automated workflow, true modularity must incorporate device, componentry, and sample distribution. True modular automation adapts and re-adapts to your science, your technology, and your organization. When considering hardware, remember that hardware is a tool. It’s up to you to determine the best tool or tools that will help you to further your scientific discovery. Hardware manufacturers naturally focus on their hardware as being the solution for a given workflow, but in reality, hardware is one of three considerations in your overall and ideal automated solution.

Category 2 – Software

In every corner of the life sciences – and indeed all aspects of science generally – digital transformation is flourishing, rapidly expanding, and changing our collective approach to communication as well as data collection and analysis.

This epic change will help to propel scientific discovery by making scientific data FAIR. We don’t just mean impartial and free from bias. We mean adherent to the FAIR Principles laid forth by the GO FAIR initiative. According to these four principles, data should be

- Findable – all data is easily found by humans and computers and associated with a persistent identifier.

- Accessible – all data is understandable by humans, computers, and devices and stored in a trusted repository.

- Interoperable – all data share a formal, accessible, shared, and broadly applicable language.

- Reusable – all data is well-described, with a clear usage license and accurate information on provenance.

By connecting various tools through the Internet of Things (IoT), you can unleash the power of advanced laboratory automation and turn your lab into a data factory. This enables a seamless flow of data streams across your organization, turning digital transformation into something truly remarkable.

This makes software an important second consideration in your automated solution. While software is available for many different purposes and with different capabilities, true lab automation software must move beyond mere workflow scheduling and process management. It must produce data quickly and reliably so that you can make faster and better decisions than ever before.

Category 3 – Peopleware

People are the lifeblood behind hardware and software solutions used by the life science industry. Hardware and software innovations would not be possible without teams of specialists behind their development. This is why peopleware should be the final consideration in your automated workflow solution.

Unlike artificial intelligence (AI), people are capable of critical thinking and collaboration, which are particularly essential throughout the iterative design, build, test, and learn (DBTL) process.

- Design – People fathom the original hardware or software product idea. This might start by reacting to a known market shortcoming or identifying an unmet need. Using this information, they define goals and requirements for the potential product. This step also includes brainstorming, considering multiple perspectives, simulating models, and developing a detailed development plan and timeline.

- Build – Once the design plan is clear, engineers and expert technicians can begin to construct the solution. This may be creating a physical prototype or writing an AI algorithm to perform a task.

- Test – After an initial solution is designed and built, it undergoes rigorous tests to evaluate its functionality, performance, reliability and reproducibility, and safety against the defined goals and requirements.

- Learn – This final stage includes compiling all analyses and feedback from internal teams, potential users, and other stakeholders. This information is used to identify valuable insights or shortcomings and also to inform necessary product refinements.

This process can be repeated several times to ensure continuous improvement, optimize performance, and ensure that the product meets changing market needs.

Naturally, great peopleware extends beyond product development, ensuring that each individual product complies with exacting standards and optimal performance criteria prior to customer use.

After the product is integrated into your lab’s automated workflow, Interactive and personalized training sessions help you to hone your skills and optimize the hardware or software in context of the automated workflow. Finally, proactive maintenance and service contracts, along with responsive technical and applications support, help you to extract the most from your automated workflow while extending its lifespan.

Successful Automated Workflows are More Than the Sum of Their Parts

Taken separately, hardware, software, and people are all important in a laboratory workflow, but when combined, they become an all-powerful trichotomy to propel your path to success.

Hardware represents the tools for your lab to complete its work. Software drives hardware and creates interconnectivity across your lab and organization so that your teams can make better decisions, faster. Finally, people actualize and support your lab automation solutions. These three components work harmoniously in a symbiotic relationship so that scientists can truly embrace and use lab automation to its maximum potential.

FAQs

What are the key components of a lab automation solution?

- Hardware: Robots, sample conveyance systems, devices, and other equipment that perform routine tasks.

- Software: Controls laboratory automation hardware and manages data development and flow.

- Peopleware: The people who design, implement, and use automation solutions to gain scientific insight.

What is the role of hardware in lab automation?

Hardware in lab automation is used to do the physical work in automated laboratory processes, such as sample preparation and/or analysis across a wide variety of scientific applications.

Hardware includes devices such as analytical instrumentation, laboratory equipment, robotic arms, and sample conveyance systems, to name a few. Hardware is critical because it allows scientists to focus on higher-order tasks with the confidence that manual work was performed quickly, repeatably, and reproducibility.

How does software contribute to lab automation?

Software is essential in the modern lab because it allows all of your devices to be under control, while democratizing workflows, maintaining the integrity of precious samples, allowing unconstrained collaboration, and more. Examples of how software contributes to laboratory automation include: Laboratory information management systems (LIMS) that store and keep track of laboratory data. Electronic lab notebooks (ELNs), used to store and organize laboratory notes. Data analysis software which is utilized to analyze laboratory data and create reports and visualizations.

Why is peopleware important in automated workflows?

People and the care of people are why we pursue scientific knowledge to begin with. Peopleware is essential to the success of any laboratory automation project because they design, implement, and use the automated workflows enabling the generation of data to insight. People are also needed to troubleshoot issues as they arise, and (re)adapt to changing scientific, technological, and organizational landscapes.

What are the challenges and considerations when implementing lab automation?

There are a number of challenges and considerations when implementing lab automation. These include:

- Cost: Lab automation can be expensive. The cost of the equipment, software, and peopleware can all add up.

- Complexity: Lab automation can be complex to design, implement, and use. It is important to have a clear understanding of the requirements – even those beyond workflow – before starting a laboratory automation project.

- Change management: Lab automation can change the way work is done. It is important to manage change effectively and to get buy-in from all stakeholders.

How does lab automation integrate with existing laboratory equipment?

Lab automation can be integrated with existing laboratory equipment in a variety of ways. The most common way is to use software to control the equipment. Another way is to use hardware adapters to connect the equipment to the automation system.